- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-29 Origin: Site

Thermal expansion is a critical factor that influences the quality of steel castings, particularly when dealing with high-performance applications where precision and structural integrity are non-negotiable. Ceramic foundry sand offers a superior solution for reducing thermal expansion defects, such as cracking and micro-cracks, which are common issues in steel casting. At Shanxi Taiyue Abrasive, we specialize in providing high-quality ceramic foundry sand, which not only improves casting precision but also reduces defects caused by thermal expansion. This article delves into the mechanisms through which ceramic foundry sand helps minimize thermal expansion defects and enhance steel casting quality.

Thermal expansion is the tendency of a material to change its dimensions when subjected to temperature fluctuations. In steel casting, thermal expansion plays a pivotal role in the final quality of the casting. When the mold or core material expands unevenly during the heating and cooling cycles, it can lead to a variety of defects in the casting.

Thermal expansion causes differential stress within the mold and the steel casting, leading to cracks or micro-cracks. These defects often occur during the cooling phase, when the material shrinks as it solidifies. However, if the mold material has a high thermal expansion rate, it may expand while the steel cools, causing tension that results in cracks. Additionally, as the steel expands, it can put excessive pressure on the mold, causing deformation and further defects.

Cracking is one of the most significant defects caused by thermal expansion, and it can compromise the structural integrity of the final casting. Micro-cracks can often go unnoticed, but they can lead to weakening of the steel casting, which could affect its performance in critical applications. Reducing the thermal expansion rate of the mold material is therefore crucial for preventing such defects.

The key to reducing thermal expansion defects in steel casting lies in the properties of the molding material. Ceramic foundry sand, made from high-quality bauxite, has a lower thermal expansion rate compared to traditional materials like silica sand, making it an ideal choice for high-precision casting.

One of the primary advantages of ceramic foundry sand is its low thermal expansion coefficient. This means that ceramic foundry sand expands and contracts less when exposed to temperature changes compared to traditional sands. Because the material experiences less expansion during the heating and cooling phases, it exerts less stress on the casting and the mold, significantly reducing the risk of cracks and deformation.

The lower thermal expansion of ceramic foundry sand ensures that the mold remains stable during the entire casting process, helping to maintain the dimensional integrity of the mold and the final casting. This is particularly crucial for steel castings, where high precision is required, especially in components that undergo high-stress conditions.

The integrity of the mold plays a critical role in the quality of the casting, and it is influenced by the material's thermal properties. Ceramic foundry sand contributes to mold integrity and casting stability by providing better resistance to thermal stress.

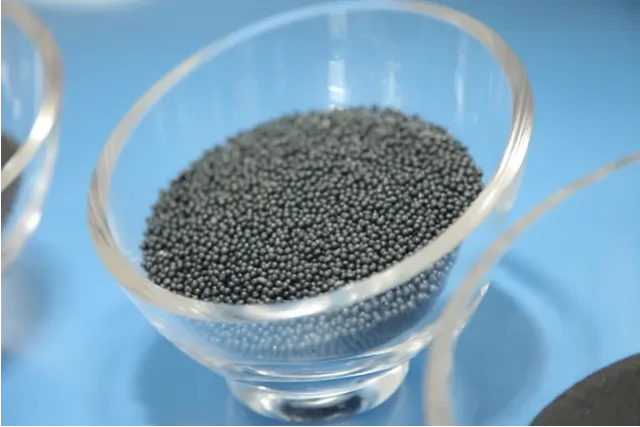

The spherical shape of ceramic foundry sand allows for better packing within the mold, ensuring more even heat distribution. This uniform packing leads to more consistent thermal expansion across the mold, which helps prevent uneven stress on the casting. In contrast, angular materials like silica sand can create uneven packing, leading to localized stress points and a higher likelihood of cracks forming during the casting process.

The smooth grains of ceramic foundry sand also improve the flowability and compaction of the mold, leading to better filling of intricate mold cavities. This enhanced packing, combined with the material’s low thermal expansion, results in more stable and consistent mold behavior, which is crucial for achieving high-quality castings with fewer defects.

Ceramic foundry sand has high refractoriness, meaning it can withstand extremely high temperatures without breaking down. This property ensures that the sand retains its strength and stability even under the intense heat involved in steel casting. Silica sand, on the other hand, can suffer from decomposition and dimensional changes at high temperatures, leading to instability and the potential for cracks and other defects.

The superior heat resistance of ceramic foundry sand ensures that the mold can handle the molten metal’s high temperatures without expanding excessively or deforming, which is essential for producing strong, defect-free castings.

The impact of ceramic foundry sand on reducing thermal expansion defects is evident in real-world casting scenarios. Several foundries have reported a significant reduction in defects such as thermal cracking and deformation after switching to ceramic foundry sand for their molds.

Below is a table showing the incidence of common casting defects when using ceramic foundry sand versus traditional silica sand.

Table: Defect Incidence Rates

Defect Type | With Ceramic Sand | With Silica Sand |

Thermal Cracks | Lower | Higher |

Deformation | Lower | Higher |

Rework Rate | Lower | Higher |

As the table indicates, ceramic foundry sand significantly reduces the incidence of thermal cracks, deformation, and the need for rework compared to traditional silica sand. This leads to fewer rejected parts and reduced downtime in the production process, making ceramic foundry sand a more efficient and cost-effective choice for foundries.

While ceramic foundry sand offers numerous advantages for steel casting, its successful implementation requires careful consideration of several factors related to particle size, binder systems, and overall process integration.

The particle size distribution of ceramic foundry sand plays a crucial role in determining how well it packs within the mold and how effectively it can withstand thermal expansion. Foundries must ensure that the sand is processed to the appropriate particle size to achieve optimal flowability and mold strength. Additionally, selecting the right binder system is essential to ensure that the sand holds together effectively during the casting process.

Integrating ceramic foundry sand into the casting process requires some adjustments to existing systems, but the long-term benefits in terms of quality and efficiency outweigh the initial setup costs. Foundries can benefit from training and consultation on best practices for using ceramic sand to maximize its potential.

In conclusion, ceramic foundry sand is an invaluable material for reducing thermal expansion defects in steel castings. Its low thermal expansion coefficient, high refractoriness, and superior packing ability make it the ideal choice for foundries that require high-precision, defect-free castings. By switching to ceramic foundry sand, foundries can achieve better dimensional control, fewer defects, and improved mold integrity, leading to higher-quality steel castings and increased operational efficiency.

At Shanxi Taiyue Abrasive, we are committed to providing high-quality ceramic foundry sand that helps foundries optimize their casting processes and improve the overall quality of their steel castings. Our ceramic foundry sand is designed to reduce thermal expansion defects, enhance mold stability, and deliver superior performance for a wide range of casting applications. If you are looking to improve your steel casting process and reduce defects, ceramic foundry sand is the solution you need. Contact us today to learn more!

1. How does ceramic foundry sand reduce thermal expansion defects?

Ceramic foundry sand has a low thermal expansion coefficient, which minimizes the stress on molds during the casting process, leading to fewer thermal cracks and defects.

2. What are the key advantages of ceramic foundry sand over silica sand?

Ceramic foundry sand offers better dimensional accuracy, fewer defects, lower rework rates, and superior heat resistance compared to silica sand.

3. How does the shape of ceramic foundry sand affect mold integrity?

The spherical shape of ceramic foundry sand ensures better packing and even distribution of thermal stress, improving mold integrity and reducing the risk of cracks.

4. Can ceramic foundry sand be used in all types of steel casting?

Yes, ceramic foundry sand is suitable for a wide range of steel casting processes, including those requiring high precision and complex structures.