- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-30 Origin: Site

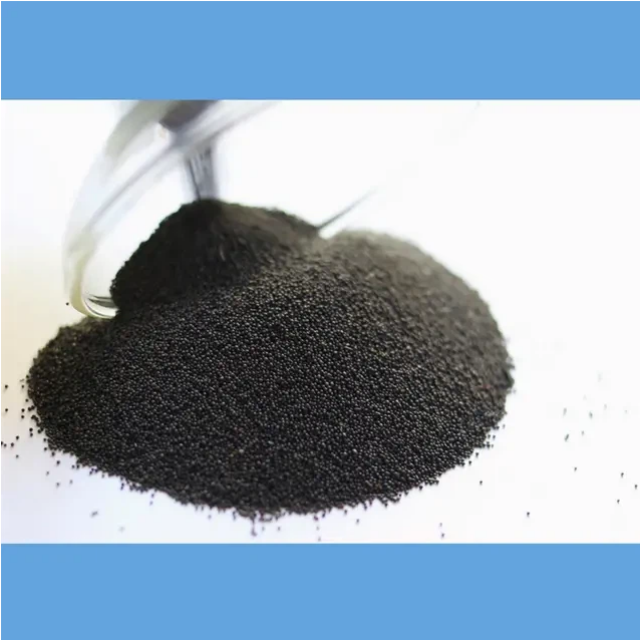

When sourcing materials for your foundry, the quality and reliability of the sand you use play a crucial role in ensuring the success of your casting process. Ceramic foundry sand is a superior choice for high-precision casting applications due to its remarkable properties, such as low thermal expansion and high refractoriness. As a leading supplier of high-quality ceramic foundry sand, Shanxi Taiyue Abrasive is committed to providing the best material for your foundry needs. In this article, we will explore the key quality attributes of ceramic foundry sand, important industry standards such as AFS GFN (grain fineness number), and how to assess a supplier’s consistency and reliability. By understanding these key factors, you can ensure that you select the right supplier to support your foundry’s production goals.

Choosing the right ceramic foundry sand is essential for ensuring the success of your casting projects. Several important quality attributes should be considered when evaluating different sand options. These attributes will determine the sand's performance and how well it meets the specific requirements of your casting processes.

The roundness of the sand grains is crucial for achieving smooth and consistent mold surfaces. Ceramic foundry sand, due to its spherical or near-spherical shape, provides better flowability and packing within the mold. This allows for more uniform mold filling, reducing the likelihood of defects such as air pockets or incomplete mold filling.

Size distribution is another important factor. The particle size of the sand should be uniform to ensure consistent packing and prevent gaps in the mold. Well-graded sand ensures that the mold is filled evenly and reduces the chances of porosity in the final casting.

Refractoriness, or the ability of the sand to withstand high temperatures without breaking down, is another key property of ceramic foundry sand. This characteristic makes it ideal for high-temperature applications such as steel and alloy casting, as it ensures the sand will maintain its structural integrity under extreme heat.

Finally, crush resistance refers to the ability of the sand to resist mechanical stress during molding and casting. Ceramic foundry sand exhibits excellent crush resistance, which means it can withstand the forces exerted on it during the casting process without breaking down.

To ensure the best performance and consistency in your casting processes, it’s essential to choose a supplier who adheres to industry standards and certifications. One such important standard is the AFS GFN (American Foundry Society Grain Fineness Number).

The AFS GFN is a standard used to measure the grain size of foundry sands. It represents the average particle size of the sand, and it plays a critical role in determining the mold’s performance. A lower GFN indicates finer sand, which provides better surface finish and packing, while a higher GFN indicates coarser sand that may have less uniformity in mold filling.

Ceramic foundry sand typically has a finely graded GFN, which ensures better mold packing and improved casting surface finishes. For precision casting, such as in the aerospace or automotive industries, choosing sand with the right GFN is vital for achieving the highest quality results.

In addition to AFS GFN, other certifications and standards, such as ISO certifications or adherence to local environmental regulations, can indicate a supplier’s commitment to quality and sustainability.

When selecting a supplier for ceramic foundry sand, consistency and reliability are key factors to consider. You want to ensure that the supplier’s products meet your quality standards over time, and that any variations in product quality are minimized.

A reliable supplier will conduct regular lab testing to ensure that each batch of ceramic foundry sand meets the required specifications. This testing should focus on parameters such as particle size, roundness, refractoriness, and crush resistance. Regular lab testing provides you with confidence that the sand will perform consistently in your foundry, reducing the likelihood of defects in your final castings.

Batch uniformity is also an essential factor. Inconsistent batches can lead to issues such as uneven mold packing, which may cause casting defects. Choose a supplier who ensures that each batch of ceramic foundry sand maintains uniformity, so you can rely on consistent performance throughout your casting processes.

When evaluating potential suppliers of ceramic foundry sand, it’s important to compare key quality indicators. Below is a table that outlines some of the critical criteria to consider when assessing the quality of a supplier’s products.

Table: Supplier Evaluation Checklist

Evaluation Criterion | What It Means |

Grain Fineness (AFS GFN) | Uniform mold packing for consistent casting quality |

Refractoriness | High-temperature resistance for reliable performance in casting |

Recyclability | Lower cost and less waste due to high recycling potential |

Past Performance Data | Verified casting results to ensure reliability and quality |

By evaluating these factors, you can assess whether a supplier’s ceramic foundry sand meets the quality standards required for your foundry’s needs. A reliable supplier will provide consistent, high-quality sand that helps you achieve the best casting results.

Choosing a supplier for ceramic foundry sand is not just about the product itself; after-sales support and technical assistance play a crucial role in ensuring your foundry operations run smoothly. A supplier who offers strong technical support can help you optimize your casting processes and troubleshoot any issues that arise.

A good supplier will offer process consultation services to help you integrate ceramic foundry sand into your specific casting requirements. This includes providing advice on how to optimize your molding process for better efficiency and quality. Additionally, technical support for testing the sand’s performance in your foundry will ensure that you are getting the most out of the material.

By choosing a supplier who is committed to offering comprehensive after-sales support, you ensure that you have the resources needed to address any challenges and continually improve your foundry’s operations.

Ultimately, when selecting a supplier for ceramic foundry sand, it’s essential to view the relationship as a partnership rather than a simple transaction. A reliable supplier should offer not only high-quality products but also exceptional service, consistency, and support. By choosing a supplier who understands your needs and is dedicated to ensuring your success, you can achieve the best possible outcomes in your casting processes.

Shanxi Taiyue Abrasive is committed to being a trusted partner for foundries worldwide, providing high-quality ceramic foundry sand and comprehensive support to help you optimize your casting operations. Our products are designed to meet the highest standards, ensuring your foundry can achieve superior casting quality with reduced defects and increased efficiency.

Selecting the right supplier for ceramic foundry sand is essential for the success of your foundry operations. Key factors such as grain fineness, refractoriness, recyclability, and consistent performance are all critical for ensuring high-quality castings. At Shanxi Taiyue Abrasive, we are proud to offer high-quality ceramic foundry sand that meets the highest industry standards, backed by strong after-sales support and technical assistance. For more information on how ceramic foundry sand can improve your casting processes, contact us today!

1. How do I assess the quality of ceramic foundry sand?

Key factors to assess include grain fineness (AFS GFN), refractoriness, and recyclability. Additionally, ensure batch uniformity and consistent lab testing results.

2. What is AFS GFN, and why is it important?

AFS GFN (Grain Fineness Number) measures the particle size of foundry sand. It is crucial for determining mold packing quality, which affects the surface finish and dimensional accuracy of castings.

3. Can ceramic foundry sand be recycled?

Yes, ceramic foundry sand is highly recyclable, making it a cost-effective and environmentally friendly choice for foundries.

4. What should I look for in a ceramic foundry sand supplier?

Look for a supplier who offers consistent, high-quality products, strong after-sales support, and a commitment to meeting industry standards like AFS GFN.